BRS-ENGINEERING

BRS-Edition Dragon Ultra CF

BRS-Edition Dragon Ultra CF

Impossible de charger la disponibilité du service de retrait

Background

Since 2020, extruding carbon fiber filled material gave me challenges to find an adequate hotend that can last in time, easy and inexpensive to fix, with a high flow, and a compact form factor.

I tried Mosquito, Rapido, Takoto, Nova, Dragon, Dragonfly, Goliath, V6 and more... All this hotends got advantages, but lack of some spec regarding CF.

Heatbreak were the main issue, had to change them on monthly basis, which was a pain depending the catastrophy you are facing

Simple, durable, reliable.

Here I propose you my actual solution, result of the last 6 years experience and tests, the one giving me minimum downtime, and the best solution in my opinion

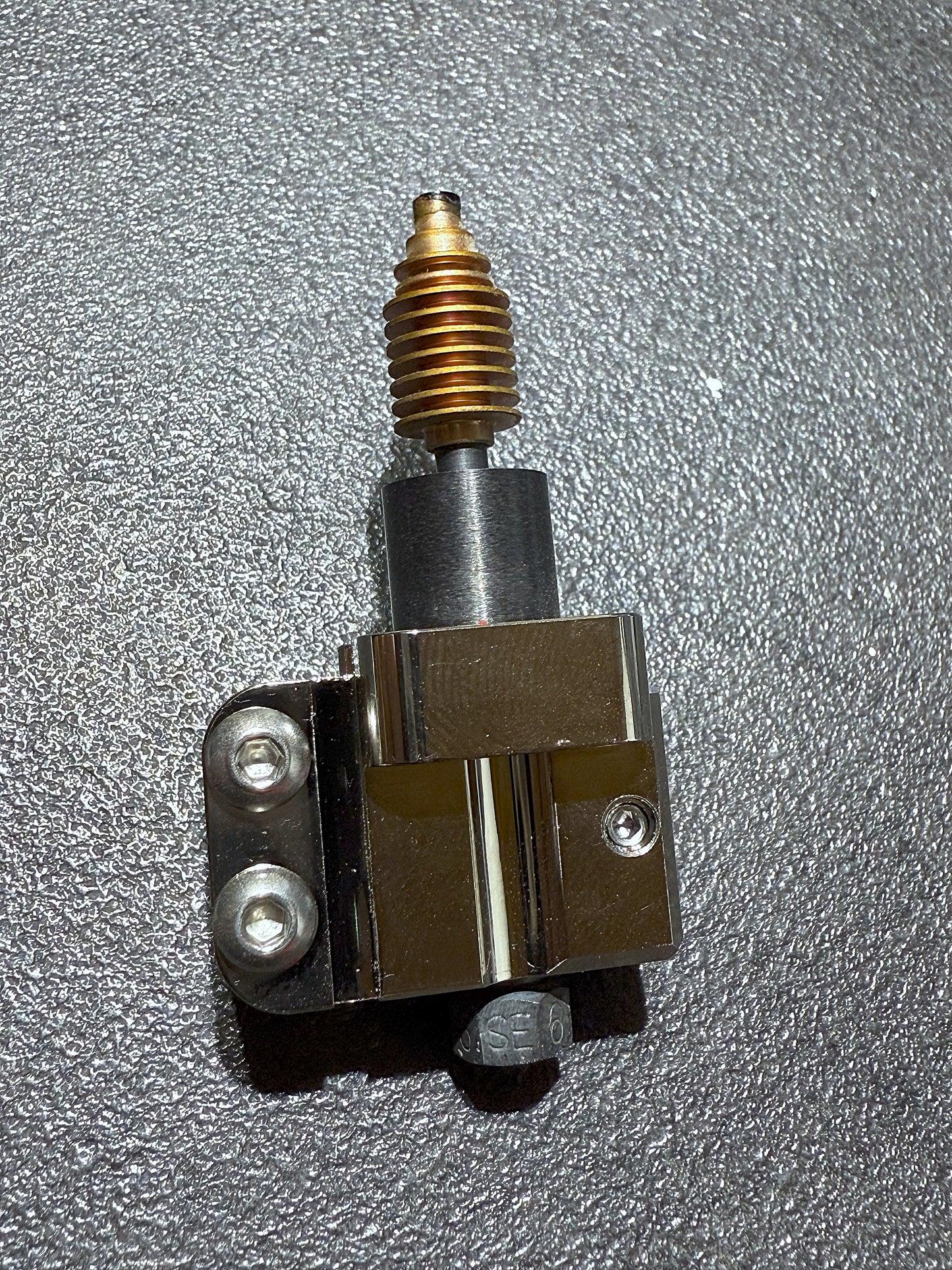

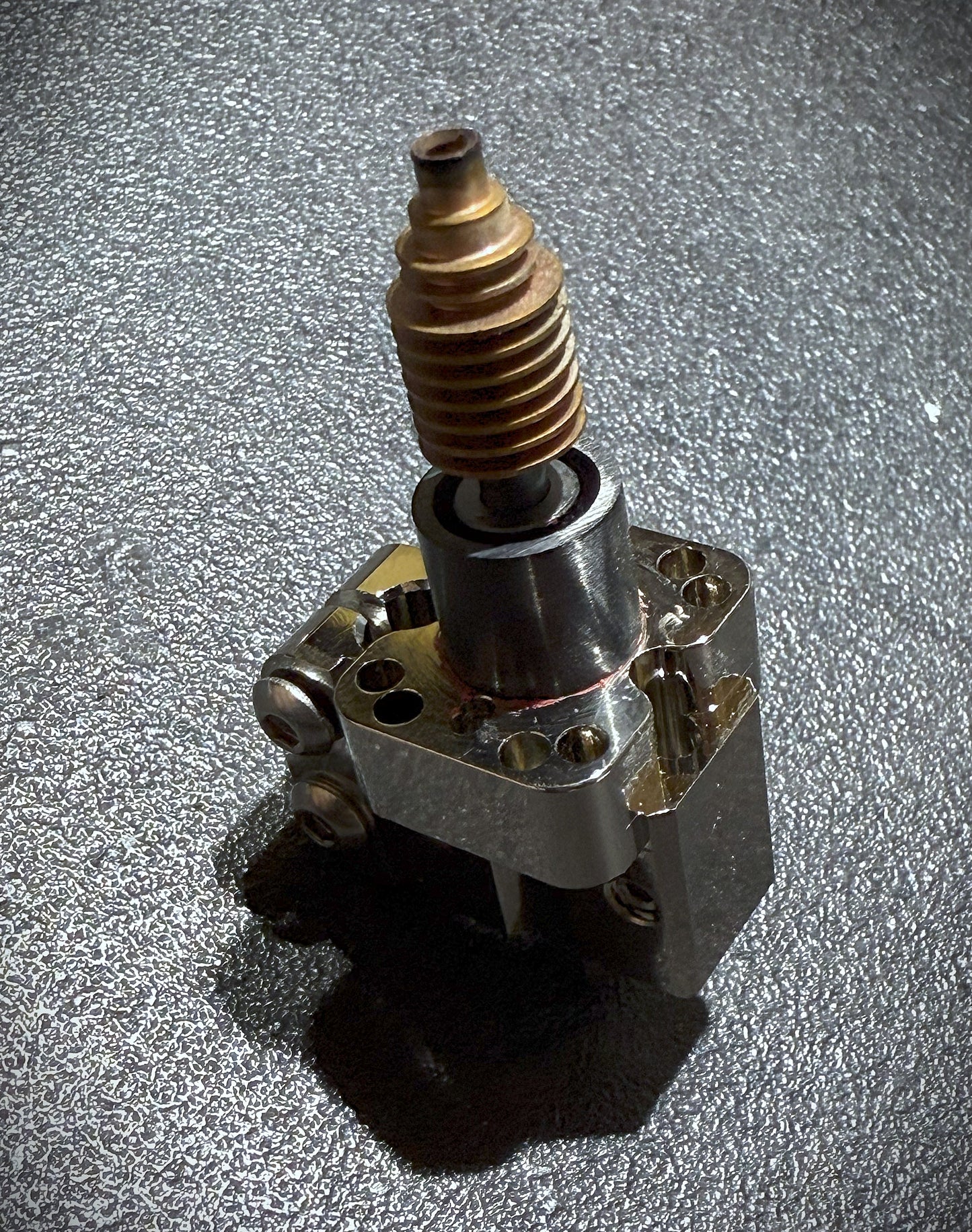

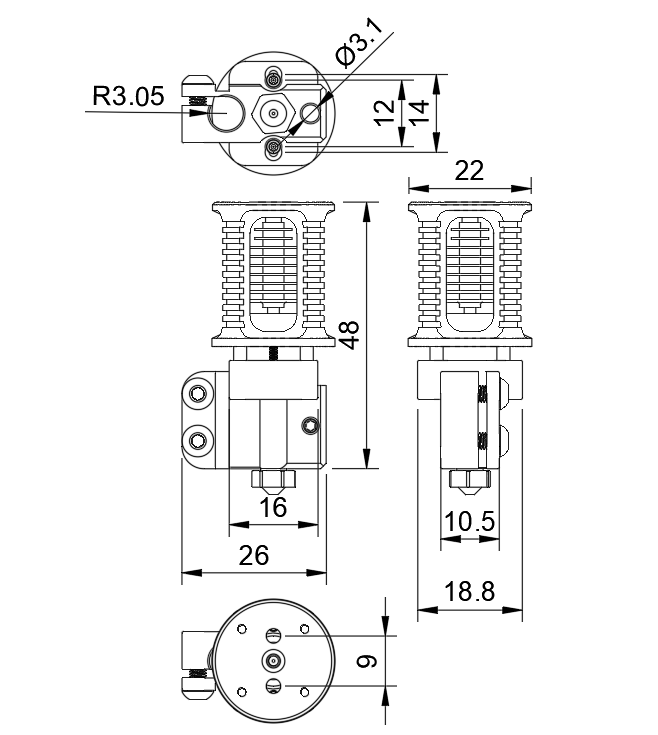

This hotend is based on a Dragon structure, quite simple in fact, with a set of aftermarket specific parts to make it durable and reliable

What is included?

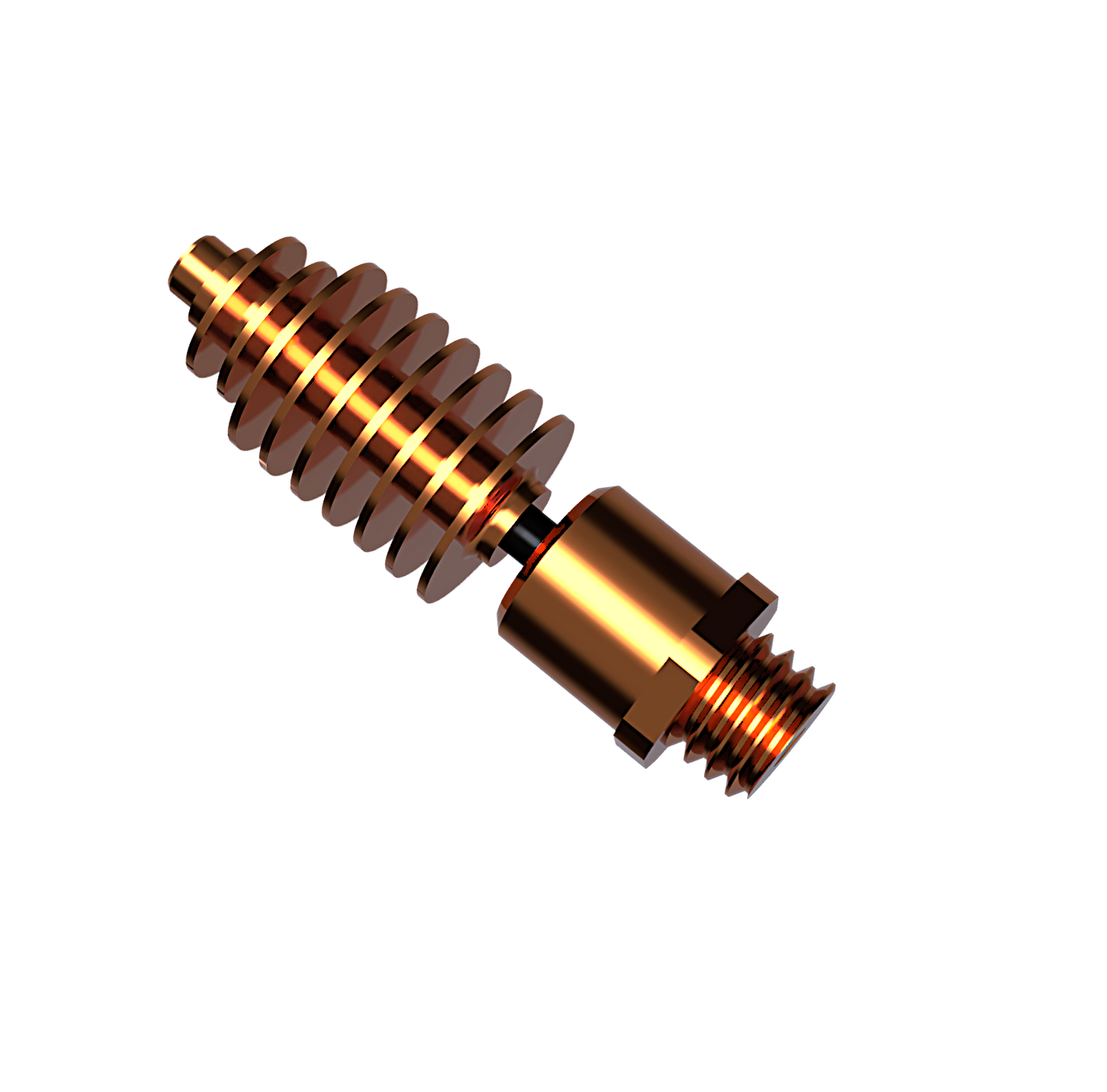

-Custom made composite heabreak with high flow capacity and ceramic ring insulation*

-Volcano style copper plated/ or alimunium heatblock with a black silicon sock

-Regular Dragon heatsink (Anodized black)

-4x Titanium spacers 2x M1.5x10mm

-70W cartridge heater / Or ceramic flat heater

-PT1000 (2 wires)

-1x M6 internal extender to use V6 nozzle into Volcano socket

-OPTIONAL: Tungsten carbide nozzle, (not coated, or with insert, this is a fully machined nozzle from tungsten carbide)

The hotend is already assembled, all screws placed at the correct torque. Heating elements assembled with boron nitrate (Heatbreak, nozzle (if chosen), PT1000 and heater)

Unit plug and play to any mount compatible with the Dragon pattern.

*Heatbreaks are basically meant to be replaced from time to time, depending a lot of factors. This composite heatbreak has been tested with 100Kg+ PA12CF15 (long fibers) over 12 months, still no issue, and that on multiple machines.